KOKI PRODUCTS

ABOUT KOKI

KOKI is known worldwide for its superior quality, technical support, product development and supply chain organization. Since its inception in Japan in 1964, KOKI has produced quality products for the soldering industry with such customers today as Apple and Toyota. KOKI products guarantee you a continuous and smooth printing process with outstanding end results in compliance with military grade standards. KOKI is continuously developing new technologies to meet the most exacting requirements for its customers. Relatively new to certain industries outside of Japan, KOKI is establishing itself as the premier solder for electrictronic manufacturing.

KOKI can provide in depth analysis reports, comparison & prototyping of your build at its facility in Japan at no cost as a KOKI customer. Including the following analysis:

Defect Analysis

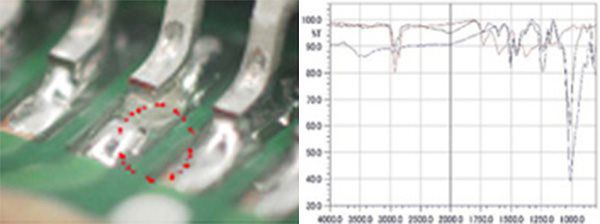

External Observation

- Observes Defective Point

- Identifies Nature of Defect

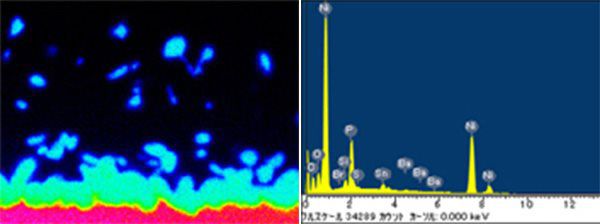

SEM/EDX Analysis

- Evaluates Quality of Plating

- Identifies Contaminating Element

FT-IR Analysis

- Analyzes Contaminating Element

- Identifies Contaminating Substance

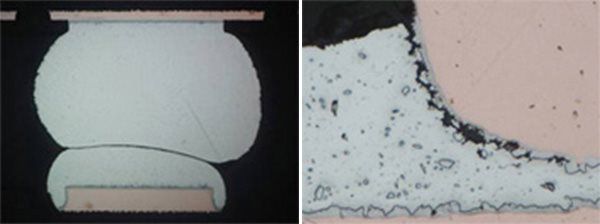

Cross Section Observation

- Evaluates IMC

- Evaluates Crystalline Structure

- Observes Defect (eg. Head-in-Pillow, Clutch, Tombstone)

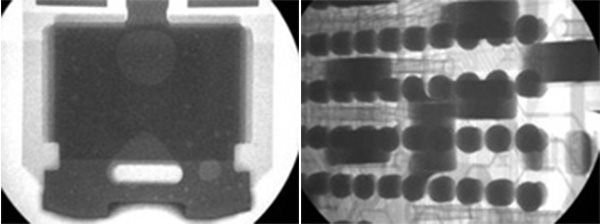

X-ray Analysis

- Observes Voiding

- Observes Head -in-Pillow Defects

Simulation

- Simulates Wetting Behavior

- Observe Warpage of Component and Board

- Suggests Recommended Reflow Conditions

Joint Strength Test

- Evaluates Shear Strength

- Evaluates Pull Strength

- Observes Breakage Mode

Thermal Shock Test

- Evaluates Joint Durability

- Observes Growth of IMC

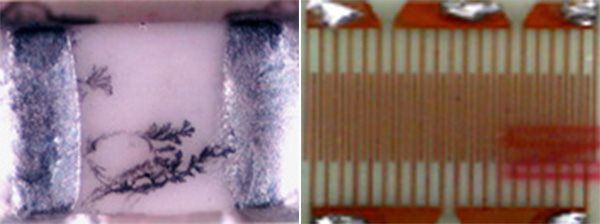

SIR Test

- Observes Electro-Migration in Thermohygrostat

- Evaluates Voltage Applied SIR

- Evaluates Drying at Normal Temp

Intercoastal Electronics is an exclusive distributor for KOKI International. Please browse through the following product datasheets and reach out to the Intercoastal Manufacturing team for samples of any product listed.

GENERAL PURPOSE SOLDER PASTE

S3X58-M500C-7 SN 3.0AG 0.5CU

KOKI International provides a general solder paste which provides good and consistent wetting Spreading to Oxidized Metal Surface.

HALOGEN FREE PIN TESTABLE SOLDER PASTE

S3X58-M650-7 SN 3.0AG 0.5CU

S3X58-M650-7 prevents the buildup of thick and sticky flux residue over the solder joint, which helps the testing probe to get the accurate readings to improve the first pass rate.

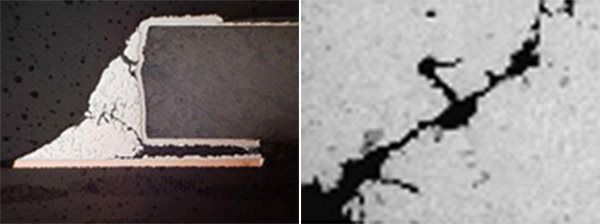

APPLICABLE FOR AIR REFLOW – CRACK FREE FLUX RESIDUE SOLDER PASTE

S3X58-CF100-2 SN 3.0AG 0.5CU

By adopting special resin into the flux, the residue remains flexible at a wider temperature range. Cracking during thermal cycling is suppressed, and ion migration due to condensation is significantly reduced.

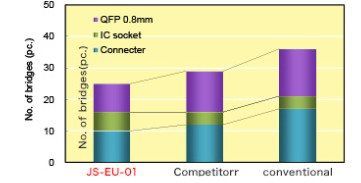

LIQUID FLUX FOR WAVE/SELECTIVE SOLDER

JS-EU-01 is made by special preparation which doesn’t use rosin at all, realizing a beautiful finish where flux residue after soldering is hardly visible.Minimizing outflow of solid content due to the heat and pressure of waving, the rosin-free flux

remains active until the end of the process. Realizes amazingly consistent solder workability.

TACK FLUX

Halogen-free tack flux with high surface insulation resistance

In compliance with JEITA ET-7304A, halogen-free tack flux TF-M881R retains high thermal resistance and ensures good melting properties unlike conventional halogen-free counterparts.In addition, the product is reliable with high surface insulation resistance, making it suitable for use in fine pitch applications.

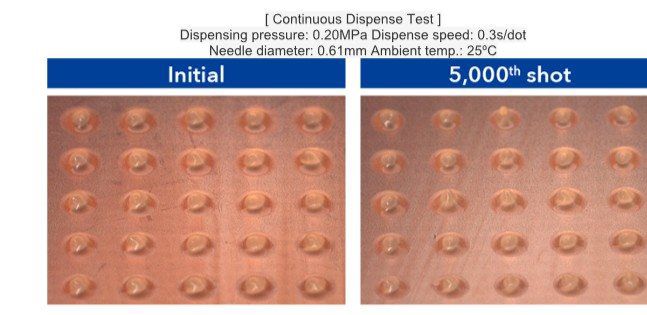

Dispense shape of TF-M881R is stable and consistenteven during continuous dispensing.It maintains its high tackiness over 72 hours which helps secure the BGA and CSP components.

FLUX CORDED SOLDER WIRE

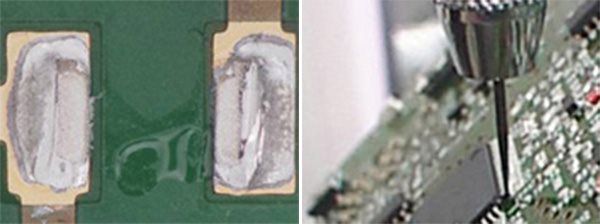

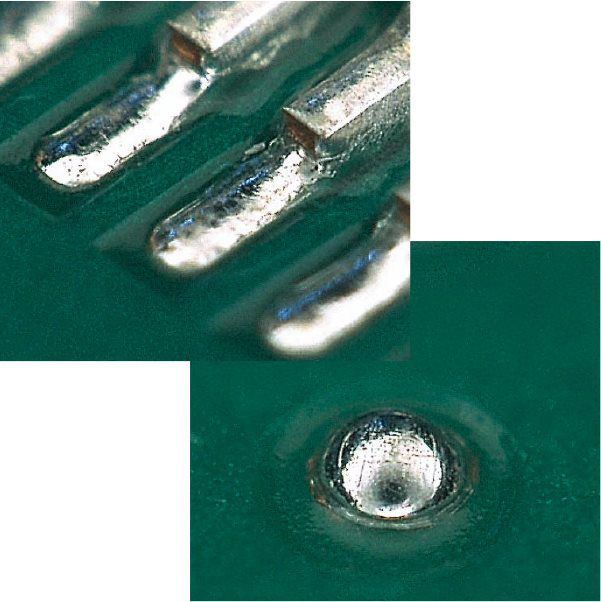

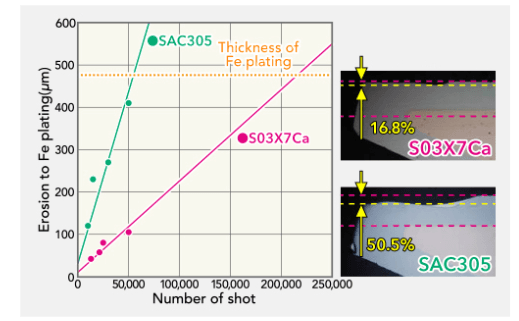

Inhibits erosion of Fe plating

Co added to S03X7Ca-72M forms a barrier layer at the iron tip surface, which inhibits erosion of the tip. S03X7Ca-72M significantly reduces wear of iron tips compared to regular lead-free solder.

Iron tips after 10,000 shots.

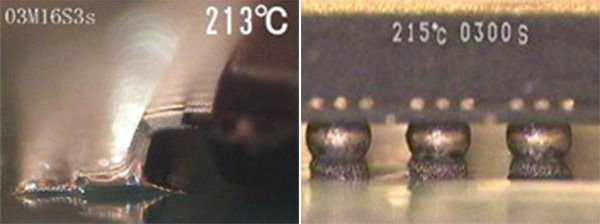

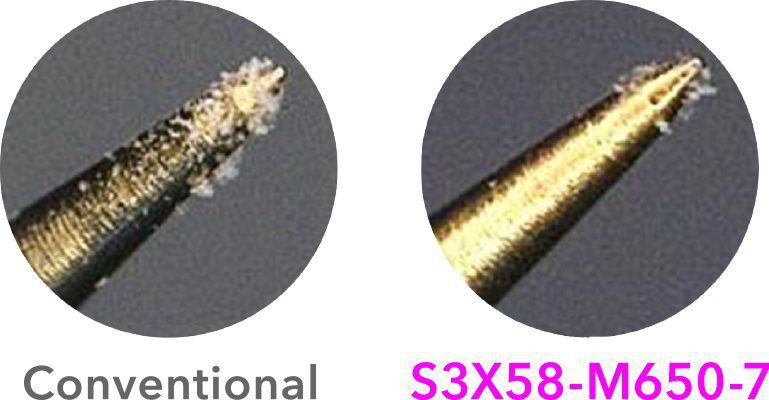

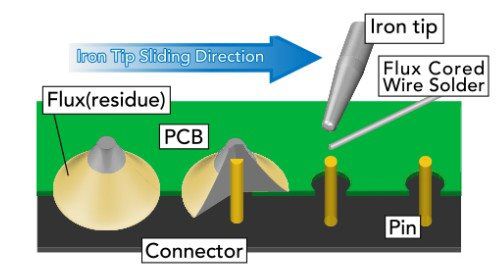

Prevents bridging in slide soldering

72M series contain new activators for improved wettability and new resin composition for better flux coverage. They can prevent bridging even at defect prone conditions such as low iron tip temperature or fast sliding speed.

HEAT CURABLE SMT ADHESIVE

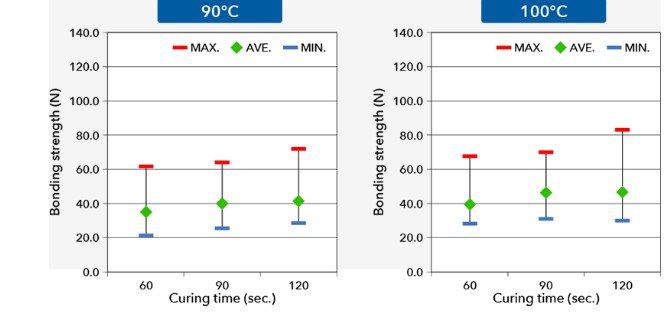

Low curing temperature mitigates damage to the PCB and the

components

JU-90LT-3 cures at low temperatures around 90-100℃, reducing the level of oxidation for the components and substrate.It enables improvement in the overall product quality and first time product quality.

[ Curing Condition and Bonding Strength ]